OUR SERVICES

CERTIFIED INSPECTORS QUALIFIED

Inspection Company

QA/QC LEAD, LLC

QA/QC LEAD inspection has a pool of fully certified inspectors qualified to handle the NDT inspections. They are all trained and certified ASNT NDT Level II or Level III, and conduct the inspections as per the official international standards.

CONTACT US TODAY!

These are the NDT methods that we currently provide to evaluate materials, components, and welds.

Magnetic Testing (MT)

Magnetic particle testing (MT) is used to locate surface and slight subsurface discontinuities or defects in ferromagnetic materials. Such flaws present in a magnetized part will cause a magnetic field (i.e. flux) to leave the part. If magnetic particles are applied to this surface, they will be held in place by the flux leakage to give a visual indication. QA/QC LEAD NDT provides the following services with this technique:

Yokes

Direct Current (DC) Yokes

Portable Alternate Current (AC) Yokes

Magnetic Particles

Dry Power

Wet System Particles (Fluorescent, Color Contrast)

Ultrasonic Testing (UT)

Ultrasonic testing (UT) is a non-destructive inspection method that uses high frequency sound waves (ultrasound) that are above the range of human hearing, to measure geometric and physical properties in materials. One of the primary benefits of UT is that it is considered to be a truly volumetric test. UT is capable of determining not only the length and location of a flaw, but it will also providing information as to the type of flaw found. QA/QC LEAD NDT provides the following services with this technique.

Conventional UT

Crack Sizing

Conditioning Monitoring

Shear Wave Weld Inspection

RAW Material and Manufactured Products

Lamination Scans

Thickness Measurement

Hardness Testing (HBT)

Hardness Test – is typically performed by pressing a specifically dimensioned loaded object (indenter) into a flat surface of the material you are testing. The hardness is determined by measuring the depth of the indenter penetration or by measuring the size of the impression left by the indenter.

Penetrant Testing (PT)

Liquid penetrant inspection (PT) reveals surface flaws by the “bleed-out” of a penetrating medium against a contrasting background. This is done by applying a penetrant to the pre-cleaned surface and flaw of the item being inspected.

The penetrant liquid will be drawn into any surface opening by capillary action. Following the removal of the excess penetrant, an application of a developer reverses the capillary action and draws the penetrant from the flaw. The resultant indications reveal the presence of the flaw so that it can be visually inspected and evaluated. IGNITE NDT provides the following services with this technique.

Visible Penetrants

Fluorescent Penetrants

Visual Inspection (VT)

Visual inspection (VT) relies upon the detection of surface imperfections using the eye. Normally applied without the use of any additional equipment, VT can be improved by using aids such as a magnifying glass to improve its effectiveness and scope. IGNITE NDT provides the following services with this technique:

Coating Inspection

Welding Inspection

Surface Integrity

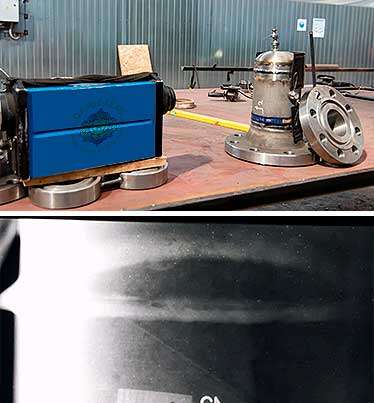

Radiographic Testing

Radiographic Testing, one of our core areas of expertise, calls for using X-rays or gamma radiography to perform full volumetric inspection to validate the soundness of welds and other components. Radiography is one of the oldest and most widely used non-destructive testing methods.

In most cases, radiographic testing is used for the evaluations of welds on pipelines, pressure vessels, piping, storage containers, and structures. QA/QC LEAD has qualified radiographers that interpret radiographs to applicable codes and standards such as API, ASME, and AWS while complying with required customer specifications.

QA/QC LEAD regularly provides high-production weld inspection services on major pipeline construction projects using Conventional Film Radiography.

Radiography is performed in accordance with applicable NRC, agreement states, or jurisdictional requirements. Highly safety precautions are used by our very experienced technicians to keep everyone safe.

OUR SAFETY

QA/QC LEAD, LLC

We are dedicated to developing a safer environment for society. Our safety performance is based on industry standards and requirements. Safety is a priority that we maintain to foster customer satisfaction and confidence. We are committed to continuing education, substantial training, and qualified performance in our quality and safety control protocol.

We Are Your Inspection Company.

QA/QC LEAD, LLC

Non-Destructive Testing (NDT)

As a leading NDT company, we provide precise welding and analysis services for industries of all types while regularly exceeding the expectations of our customers.

Third-Party Surveillance

Outsourcing your welding process does not mean you sacrifice quality. With our vendor surveillance services, we will ensure your specifications and quality standards are upheld.

Weld Consultation

We can provide you with top-to-bottom welding consultation to ensure you follow industry standards and codes. If you are a small to medium size business, let us do the heavy lifting for you.